The Parylene Deposition Process

Posted by Sean Horn

Thursday, March 22, 2012 9:00

@ 9:00 AM

The Parylene Deposition Process

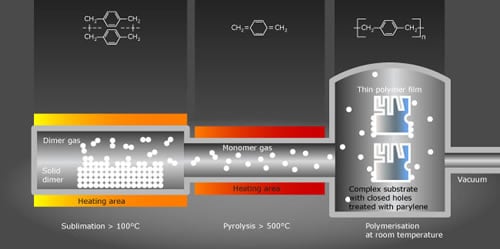

Parylene coating is applied through a vapor deposition process onto the substrate or material that is being coated. Depending on the coating type and required thickness, typical parylene deposition rates are about .2/mils per hour, so machine runs can vary from as little as 1 hour to over 24 hours. The process begins with raw dimer in solid state (these are: Parylene C, Parylene N, Parylene D, Parylene AF-4, or other variants) being placed into a loading boat, which is then inserted into the vaporizer. The raw dimer is heated between 100-150º C. At this time, the vapor is pulled, under vacuum into the furnace and heated to very high temperatures which allows for sublimation and the splitting of the molecule into a monomer. The monomer gas continues to be drawn by vacuum one molecule at a time onto the desired substrate at ambient temperatures in the coating chamber. The final stage of the parylene deposition process is the cold trap. The cold trap is cooled to between -90º and -120º C and is responsible for removing all residual parylene materials pulled through the coating chamber.

The process is visually described through figure 1 below:

Figure 1.

The parylene deposition process is relatively simple to understand, but tough to master. A thorough understanding of the process is key to controlling thickness and ensuring a successful coating cycle.

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !