What is the right conformal coating for LEDs?

Posted by Sean Horn

Thursday, June 21, 2012 11:50

@ 11:50 AM

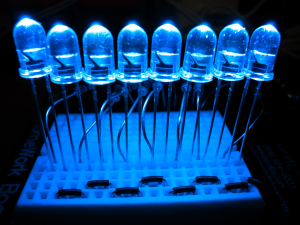

Light emitting diodes (LEDs) are a huge and growing even bigger segment of the electronics industry. LEDs are expanding into environments that demand a higher level of protection in order for the LED to function properly. One way to get this level of protection is by using conformal coating.

Acrylics

Acrylic conformal coating is great for LEDs that are looking for solid moisture protection. Acrylics should not be used on LEDs that are going into a high-solvent environment. Some acrylics have been specially formulated to be optically clear so the LED can be coated over, reducing masking time and overall cost.

Silicones

Silicone conformal coating is used whenever there are high heat requirements for the LED. Some specially manufactured silicones can offer protection beyond 200ºC. Silicones, because they are applied thicker than other coatings, also can offer a higher level of moisture protection for harsher environments.

Parylene

Parylene is an excellent choice for LEDs that are looking for the ultimate in moisture and solvent protection. While normally parylene has poor ultra violet (UV) resistance, a great alternative is to use Diamond-MT’s parylene coating for LEDs that has the benefits of parylene with UV protection built in for outdoor applications, like signage.

If you’re looking for conformal coating services for LEDs & lighting, contact Diamond-MT today. Get started by calling us at 814-535-3505 or completing a quote request.

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !