What is parylene conformal coating?

Posted by Sean Horn

Thursday, July 18, 2013 7:57

@ 7:57 AM

So you’d like to know a little something about parylene conformal coating, but were afraid to ask. You need not be ashamed. The process is so fundamental to electronic manufacturing that it can very easily be taken for granted.

Let’s start with a look at other conformal coatings and how parylene compares.

Just about every component on a printed circuit board is coated with an insulating chemical. The chemicals used can differ—parylene is one—but all serve the same purpose: to protect sensitive components against heat, moisture, any element capable of wearing down parts due to exposure. The resultant layer is a dielectric, which means that it can be polarized electrically. Processes by which the layer is applied differ. Boards can be brushed with, sprayed with, or dipped into the chemical.

Brush coating is applied by hand with something like a paintbrush. Though it’s a relatively inexpensive method, there are disadvantages. The first is cosmetic. Ever put a coat of paint onto a wall only to notice that a bunch of air bubbles have suddenly arisen? The same problem can occur when brush coating electronics. Also, not everyone is a good brush-coater, and results can be sloppy if rushed.

Spray application is a decent method, especially when applied with a capable hand. But the spray is atomized, so although the coating may be evenly distributed, it may not reach into some of the smaller cracks and crevices in a board. These areas would need to be touched-up manually, increasing cost and through-put time.

Dipping is pretty much the way you might picture it: A mechanical arm that looks like a towel bar holds the piece and is physically lowered into the chemical. This process has a major advantage, as it’s capable of coating the entire surface of the board. No crack or crevice goes unnoticed. However, a drawback is what is known as “thin tip coverage,” where a particularly sharp or thin edge carries the risk of uneven coating. Repeated coatings are usually the solution to this problem. But as you’ve probably guessed, repeated coating by any method equals a higher volume of chemical used. Higher volume means equals money, plain and simple.

Recent years have seen major improvements in conformal coating technology. Robotic automation can be programmed to selectively target hard-to-reach areas with more coating, and easily reached areas with less. Automated spraying also ensures an even regulation of materials all around, reducing the waste of chemicals. The methods outlined above require comparatively more masking—think about how you tape sections of the wall you don’t want painted—whereas selective coating needs very little.

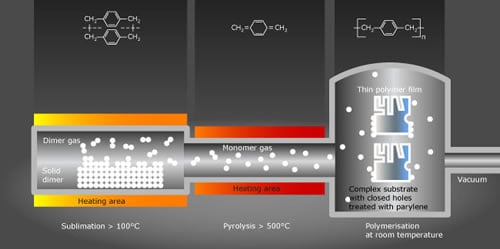

And so we come to parylene. Major advantages of this chemical include its ability to form on the surface of the board at room temperature, thereby requiring no extreme temperatures which can stress the final product. Parylene also tends to have a uniform thickness that is virtually pinhole-free. A high tensile strength, good dielectric properties, temperature- and climate-stable, and “green”—a quality that is becoming more and more desirable in these times—the list of parylene’s advantages goes on.

But that doesn’t mean there aren’t disadvantages to parylene. Processes can be more expensive when compared to other methods of coating. In addition to the potentially higher price of the raw chemical itself, the coating is done in a batch process, which means there’s a limit to how many pieces can be coated at once. Parylene coating also requires quite a bit of masking, necessitating manual labor hours.

A good assessment of your needs is the only true measure of performance when it comes to conformal coating. Other methods will arise, no doubt. The development of parylene is one example of how needs are continually met in this ever-evolving industry.

{{cta(‘a28f6b94-0c55-4b10-9b98-95ab73c76740’)}}

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !