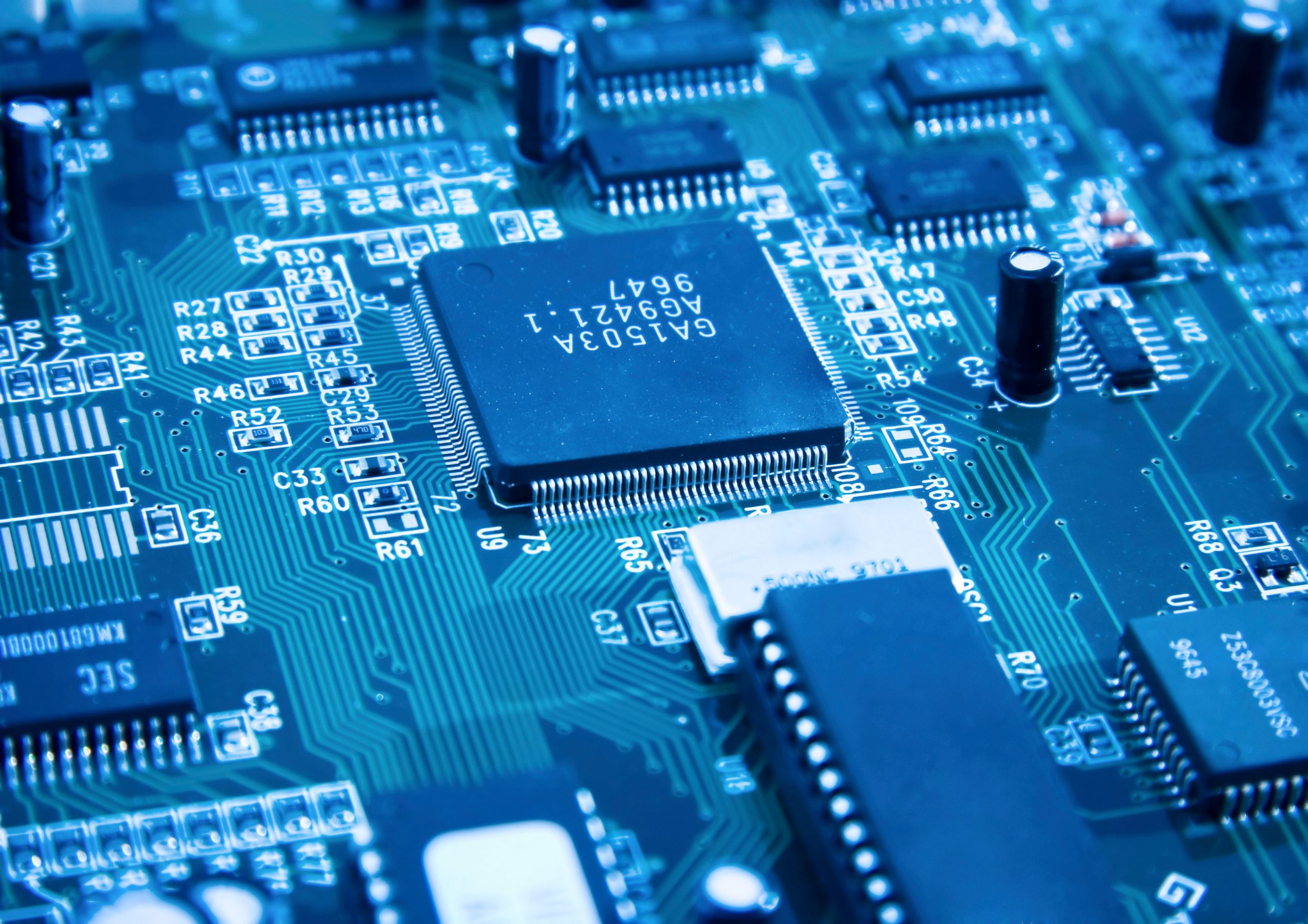

How to Choose the Best Conformal Coating for Your PCB

Posted by diamondmtblog on Fri, Oct 29, 2021

Printed circuit boards (PCBs) are the foundational building blocks of almost all modern electronic devices. Therefore they can be found almost anywhere, including in smartphones, cars, planes and many other locations. Because these boards are essential to the operation of many electronic devices, especially ones that require high dependability, they must be protected from any […]

0 Comment Click here to read/write comments