Does Parylene Adhere Chemically?

Posted by Sean Horn

Friday, April 1, 2016 8:10

@ 8:10 AM

Parylene only adheres to substrates mechanically, and this can require assistance from additive substances; parylene’s chemically-based adherence is nonexistent. Adhesion is a consequence of molecular attraction stimulating the surface unification of two dissimilar substances; their joining creates a significant physical bond between them. Of the two primary types of adhesion, chemical adhesion results when a compound joins with another, because they share sufficient mutual chemical interaction to form a bond with each other. Because parylene is chemically inert, chemical adhesion is impossible; it adheres using the other method — mechanical adhesion. Applied mechanical processes can stimulate this binding force between surface molecules.

One might think chemical substances are suitable to stimulate superior adhesion of parylene coatings, since its substrate-application employs the unique chemical vapor deposition (CVD) process. However, this is not so. In fact, the opposite is true. On their own, the chemical structures of virtually all parylene types (C, D, N, etc.) undercut good interface adhesion. The chemical vapor deposition (CVD) process that generates so many of parylene’s benefits also nullifies chemically-based substrate adhesion; only mechanical adhesion is possible.

For instance, low surface energy materials, such as Kapton (polymide), limit parylene for even mechanical applications, and entirely reject chemical adhesion, causing rapid delamination and peeling of the conformal coating. Even standard MEMS’ processes, such as lift-off or sacrificial photoresist releasing, can suffer serious delamination, wherein the parylene separates from other coating or component materials. Because chemical adhesion is impossible, mechanical methods must be used.

For instance, low surface energy materials, such as Kapton (polymide), limit parylene for even mechanical applications, and entirely reject chemical adhesion, causing rapid delamination and peeling of the conformal coating. Even standard MEMS’ processes, such as lift-off or sacrificial photoresist releasing, can suffer serious delamination, wherein the parylene separates from other coating or component materials. Because chemical adhesion is impossible, mechanical methods must be used.

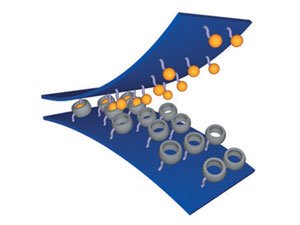

On its own, parylene does not technically adhere to substrate surfaces. It attaches to itself instead, becoming absorbed into the often microscopic pits and cracks typical of some substrate surfaces; once it is so attached, parylene doesn’t easily decompose, or otherwise relinquish its adhesion to the substance. However, if parylene is deposited on a perfectly smooth surface, the lack of inherent exterior cracking and pitting offers no imperfections to fill, significantly diminishing coating reliability.

The impossibility of chemical adherence specifies mandatory use of mechanical processes to improve parylene surface adherence. Such is the case when using parylene to conformally coat noble metals.

To learn more about parylene adhesion and how it can be improved, download our whitepaper:

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !