Is Parylene a Conformal Coating?

Posted by Sean Horn

Friday, November 10, 2017 8:06

@ 8:06 AM

If, for some reason, you are told parylene is NOT a conformal coating, simply because it has no liquid phase of application, just walk away. And maybe have yourself a good laugh. For, as you may already know, parylene has repeatedly proven itself to be the most definitive of conformal coatings, for a variety of reasons, including:

- absence of catalysts/initiators during polymerization,

- exceptional material purity, without ionic contamination,

- completely pinhole-free, chemically-inert barrier coating

- dielectric properties — reliable dielectric strength and high-frequency capacities,

- high bulk/surface resistance,

- complies with USP Class VI Plastics requirements and MIL-I-46058C/IPC-CC-830B,

- film penetration of areas as minute as 0.01mm.,

- high stress-free tensile strength,

- low permeability to moisture and gases, and

- dependable solvent and thermal endurance (-200 ‘C to +200 ‘C).

Parylene’s relative superiority is largely based on its unique application method.

Chemical Vapor Deposition (CVD)

Liquid coatings such as acrylic, epoxy, silicone and urethane are parylene’s primary competitors. Each type provides reliable conformal film protection for a specified range of uses, but none compares with the surface uniformity, versatility and longer-term resilience of parylene. Liquid coatings use brush, immersion (dip) or spray methods to apply wet coatings to substrate surfaces. Even expert application can result in pooling of the wet film on or along the component’s contours, as well as bridging, dripping or uneven surface areas that ultimately interfere with the coating’s performance and durability.

Liquid coatings such as acrylic, epoxy, silicone and urethane are parylene’s primary competitors. Each type provides reliable conformal film protection for a specified range of uses, but none compares with the surface uniformity, versatility and longer-term resilience of parylene. Liquid coatings use brush, immersion (dip) or spray methods to apply wet coatings to substrate surfaces. Even expert application can result in pooling of the wet film on or along the component’s contours, as well as bridging, dripping or uneven surface areas that ultimately interfere with the coating’s performance and durability.

In contrast, the specialized CVD application methodology converts a raw, powdered parylene dimer into a gaseous monomer, without the need for an intermediate liquid stage. The process is implemented in a chemical-vacuum chamber, with the parylene dimer inserted into the vaporizer, and heated between 100º – 150º C; solid-state parylene is transformed at the molecular level into a vapor. Process temperature must increase consistently, to 680º C, which splits the gaseous molecules into a monomer.

Drawn by vacuum onto the substrate surface one molecule-at-a-time in the coating chamber, the vaporized parylene permeates deep into the substrate surface, reaching areas often inaccessible or poorly covered by liquid materials. In cold trap, the final deposition phase, temperatures are cooled to between -90º and -120º C, removing residual parylene materials from the substrate.

In comparison, liquid coatings adhere only to the surface of covered substances. Confined to the substrate’s façade, they lack both:

- the deeper penetration of parylene into the substrate interior, and

- the consequent improved overall film adhesion and performance.

The result is a truly conformal, structurally continuous, pinhole-free coating that envelops and protects component topographies characterized by:

- crevices,

- exposed internal surfaces,

- sharp edges or

- other surface irregularities to a degree far exceeding liquids.

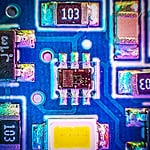

Voids in the coating common to wet material application are eliminated. These properties add to parylene’s functionality for a wide range of printed circuit boards (PCBs) and related components used by the medical device industry, commercial electronics, automotive systems, and military/aeronautics’ services (DoD and NASA).

Micro-electromechanical Systems (MEMS)/Nano-technology

In comparison to liquid coatings, parylene’s ultra-thin film thicknesses cannot be surpassed. CVD processes uniformly coat surfaces inaccessible to wet technologies, penetrating spaces as narrow as 0.01 mm., providing a conformal layer free of pinholes and impermeable to anything larger than 1.4 nanometers (nm.). This degree of MEMS/nano protection is unavailable from liquid materials.

Biocompatibility

Parylene’s MEMS/nano capacities combine with its exceptional USP Class VI biocompatibility for use as a coating for medical device applications of all kinds. It is especially well-adapted for implants. Thinner coating layers make it easier to position into small internal bodily spaces. Parylene’s superior dry-film lubricity, further facilitates implant placement and its use as a drug-delivery vehicle. Among life-critical appliances benefitting from parylene conformal coatings are CADs (cardiac-assist devices), catheters, electrosurgical tools, needles and stents.

Conclusion

Parylene also adapts well to ruggedization, for an exceptional range of specialized purposes, medical, military and commercial. In addition to PCBs, a brief list of other parylene coating applications includes backplanes, bobbins, ferrite cores, fiber optics, keypads, LEDs, mandrels, magnets, motor assemblies, optical lenses, paper, photoelectric cells, power supplies, sensors, silicon wafers, test tubes and valves. While each of the traditional liquid conformal coatings can provide a solution for some of these items, none matches parylene’s versatility or in-depth conformal adherence to targeted substrates.

To learn more about parylene, download our whitepaper here:

Download Our Guide on Parylene 101

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !