<< View SCS Blog

Can I Spray Parylene Myself?

Can I spray Parylene myself? Can Parylene even be spray coated? The short answer to both of these questions is no. Let’s take a look at Parylene’s chemistry and physics to understand why.

Polymerization Type and Process

For Parylene film to be formed and subsequently serve as a conformal coating, the dimerized starting material must undergo certain phase changes and chemical reactions. This requirement arises from its molecular structure and its polymerization mechanism. Parylene undergoes chain growth type of polymerization [1]. In this type of polymerization, a polymer chain grows by the attachment of a monomer to one of the chain ends. This process takes place one unit at a time. During Parylene polymerization, the chain ends are not finalized, and the chains that do not react are buried in the Parylene film. Later, these unreacted chain ends self terminate by reacting with oxygen once exposed to air. During Parylene deposition, no solvent is used and no by-products are formed.

Parylene Deposition Method

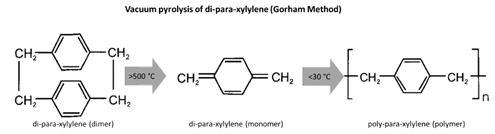

Parylene is deposited using vapor deposition polymerization (VDP) in the gas phase. The VDP process takes place in three steps: sublimation, pyrolysis and deposition. The granular or powder starting material, dimer, is weighed and inserted into the sublimation chamber. Once the system is brought under the appropriate vacuum conditions, the coating process is initiated wherein the dimer is sublimated and pyrolized, forming highly reactive monomers (Fig. 1). These monomers deposit on all surfaces in the chamber, polymerizing end-to-end, forming the thin film. In the meantime, the monomers penetrate to the smallest voids resulting in a uniform, void-free conformal coating.

As part of the continuous vacuum train, the deposition chamber also remains under vacuum. The proper vacuum conditions determine whether the deposition will be 100% efficient or not. In the presence of other gases by-products may form, decreasing the process efficiency [1]. The temperature and pressure are extremely important and require precise control for the best quality conformal coating. A professional service provider such as SCS can help you with your needs in achieving the best results.

Differences between various conformal coating deposition methods

The Parylene VDP method (Gorham [2]) makes use of reactive monomers that are produced through sublimation and pyrolysis of Parylene dimers. These highly reactive monomers are subsequently adsorbed onto the substrate and polymerize, or connect, end-to-end, forming the long-chain polymer known as Parylene.

Figure 1 Polymerization route for poly-para-xylylene (Parylene N – C16H16)

Spray, dip and brush conformal coating processes all take place in the liquid state. One thing liquid coatings often have in common is that the coating material is dissolved in an appropriate solvent and applied onto the surface of the substrate. The removal of the solvent results in the expected conformal coating. Table 1 lists a relative comparison of conformal coating systems [3]. Solution based conformal coatings can be used on arbitrarily shaped structures with ease, however one must keep in mind that these methods cannot fill in the crevices and other small spaces on the sub-micron level while Parylene VDP can. The liquid coating method is selected depending on the viscosity of the silicone, acrylic, urethane and epoxy that is being used.

Table 1 Relative Comparison of Conformal Coating Systems [3]

| System | Masking | Contamination Risk | Coating Repeatability | Viscosity Variation | Cleanliness | Cost | Transfer Efficiency |

| Dip | Yes | High | Poor | High | Poor | Low | Medium |

| Brush | Little | High | Poor | High | Poor | Lowest | Medium |

| Air Spray | Yes | Medium | Fair | Low | Poor | Medium | Low |

In the case of spray coating, the coating is deposited using a spraying tool (e.g. spray can, inert gas-filled nozzle or ultrasonic atomization). Formed droplets land on the substrate and form a conformal coating. Thickness and surface quality are hard to control compared to the VDP method. Depending on the type of polymer used, post-processing, such as a heat treatment, may be required. Good wetting, edge coverage and film adhesion can be achieved by substrate pre-treatment, controlling the precursor viscosity and spraying process variables. If process parameters are not well controlled, subsequent heat treatment may lead to cracks and delamination. Viscosity of the solvent is of high importance since a viscosity that is too low (high solvent concentration) may reduce the edge coverage but improve the sought after smoothness of the thin film, thus there is a compromise between the two. In order to achieve the best results, it is important to optimize the time for droplet landing, the droplet diameter and solution viscosity. Precision control can be managed in advanced spraying systems via nozzle flow rate control and small footprint.

Dip coating can be used for large-scale coating applications as well as PCBs. The substrate is dipped into the solution that will be coated onto the substrate. When done manually, the processor immerses the substrate or PCB in a tank of coating solution. If masking is required, components are masked by use of an appropriate masking method, coated and de-masked. Substrate cleanliness, roughness, and presence of patterns and structures are all evaluated, with the required parameters for timing and dipping velocity identified for optimal coating quality.

Brush coating is a manual process completed with a brush. PCB’s can be “painted” and the coating process can be relatively selective and precise in the macro scale, relying substantially on the skill level of the coating operator.

Among all these four methods, Parylene VDP conformal coatings offer the best uniformity, smoothness and hermeticity.

References:

[1] J. B. Fortin and T.-M. Lu, Chemical Vapor Deposition Polymerization: The Growth and Properties of Parylene Thin Films. Springer Science & Business Media, 2003.

[2] “A New, General Synthetic Method for the Preparation of Linear Poly‐p‐xylylenes – Gorham – 1966 – Journal of Polymer Science Part A-1: Polymer Chemistry – Wiley Online Library.”

[3] M. A. Reighard and N. A. Barendt, “ADVANCEMENTS IN CONFORMAL COATING PROCESS CONTROLS,” p. 10, 2000.