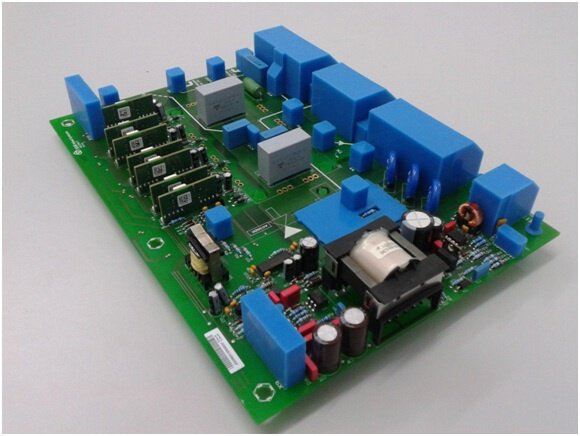

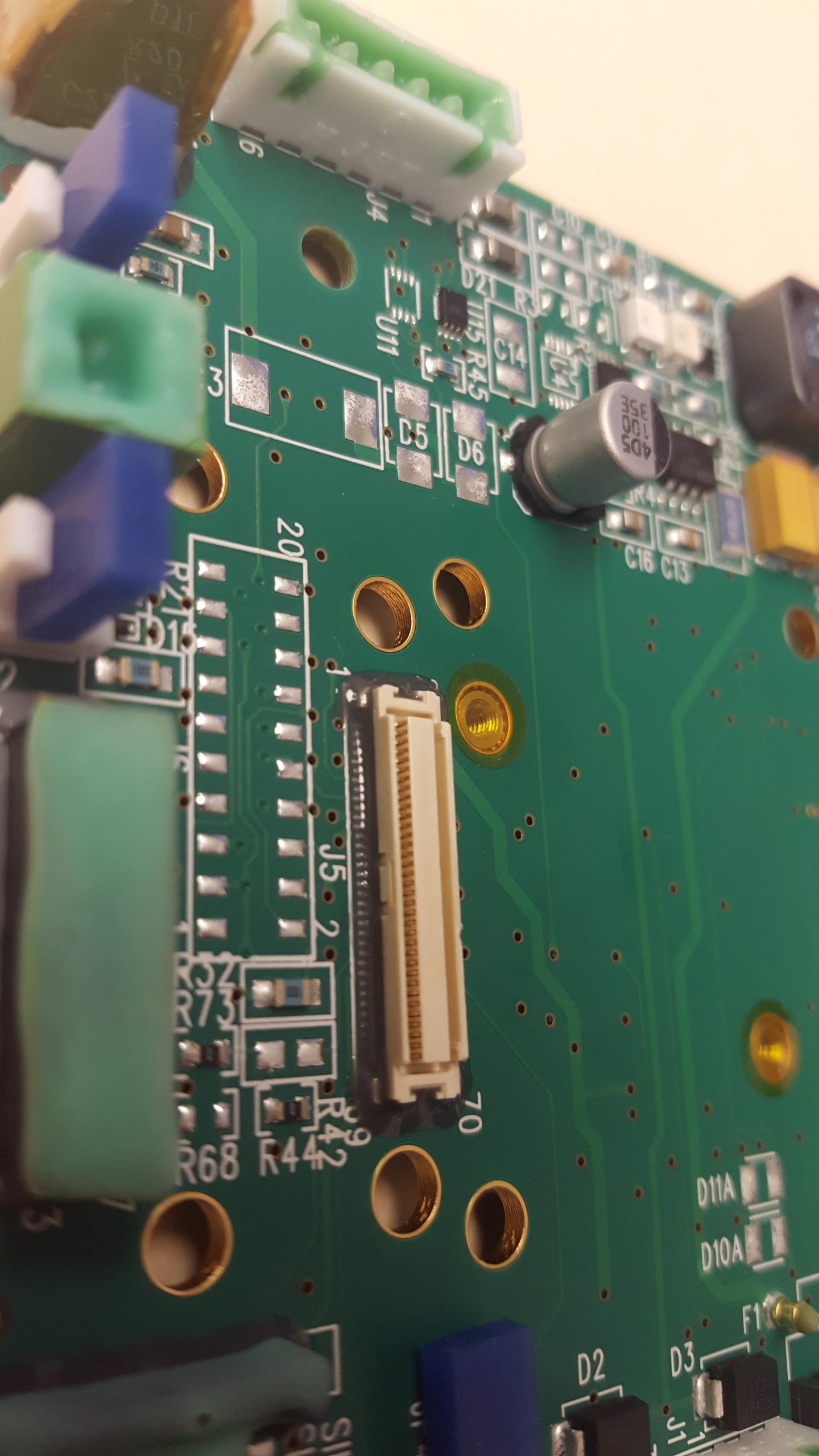

Conformal Coating Masking Boots

Posted by Sean Horn on Fri, Jan 20, 2017

Masking is necessary because conformal films like parylene and liquid coatings become insulative after drying, disturbing the performance of such critical components as connector contacts. Custom reusable boots – also called caps or plugs — protect assembly parts in those keep-out areas that must not be coated. In comparison to masking materials like tapes and […]

0 Comment Click here to read/write comments