Five Common Causes of Parylene Failure

Posted by Sean Horn

Friday, August 5, 2016 8:00

@ 8:00 AM

Parylene Conformal Coatings

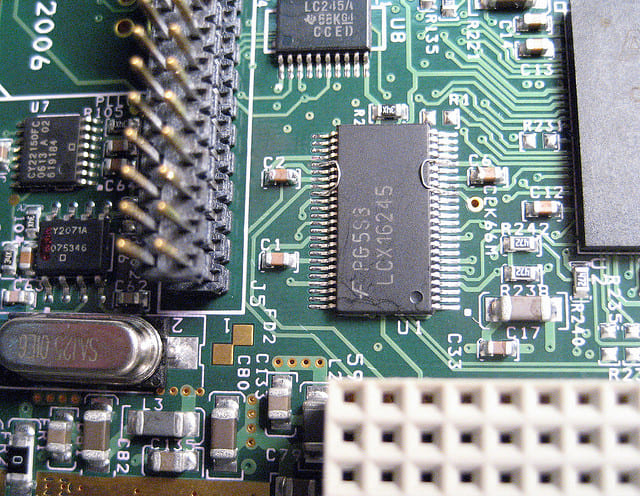

Parylene application typically generates an ultra-thin layer of electrical insulation that prevents contact between physical contaminants and the conductive elements of printed circuit boards (PCBs). Parylene also protects PCBs from the impact of corrosive vapors and moisture that may degrade their metallic components, providing a reliable barrier that significantly retards the impact of these contaminants.

Parylene is differentiated from competing conformal coatings – acrylic, epoxy, silicone and urethane – by its application process. Whereas the other conformal coatings employ some kind of wet application method – brushing, dipping or spraying are common methods — parylene’s chemical vapor deposition (CVD) process has no intermediate liquid phase. Beginning in a powdered state, the parylene is converted to a gas through cross-link polymerization at the molecular level; there is no intermediate liquid phase. The resultant vapor penetrates deep with the substrate surface to provide absolutely conformal coating that typically surpasses the performance of wet coatings on most functional levels.

While its distinctive deposition technique generates the majority of parylene’s functional advantages compared to competing coating materials, it can also be the source of parylene failure. In all cases, proper application is essential to assure parylene’s optimal performance. Otherwise, problems may emerge due to failure of the parylene film.

Five Sources of Parylene Failure

Inappropriate parylene application can result when contaminants such as stray particles, oil, metal shavings, dust, and dirt remain on assemblies during the deposition process. These disrupt parylene penetration of substrate surfaces and the creation of the uniform, pinhole-free coatings that are its best-known quality. The consequent weakened parylene film-to-surface bond, can lead to such causes of parylene failure as (1) bubbles, moisture diffusion and pinholes, (2) corrosion, (3) cracking, (4) delamination, and (5) problems from substrate outgassing.

Inappropriate parylene application can result when contaminants such as stray particles, oil, metal shavings, dust, and dirt remain on assemblies during the deposition process. These disrupt parylene penetration of substrate surfaces and the creation of the uniform, pinhole-free coatings that are its best-known quality. The consequent weakened parylene film-to-surface bond, can lead to such causes of parylene failure as (1) bubbles, moisture diffusion and pinholes, (2) corrosion, (3) cracking, (4) delamination, and (5) problems from substrate outgassing.

Moisture Diffusion and Surface Pinholes

Although parylene is highly regarded for its completely conformal covering, failure can occur if substrate surfaces are inadequately prepared. The presence of organic or inorganic contaminants can lead to imprecise coatings, as contaminants become trapped beneath the applied film, interfering with the surface penetration that is characteristic of parylene. In such cases, parylene’s ultra-thin coating can suffer from pinholes, diminishing its protective capacity. In addition, parylene-metal-parylene thin films used for micro-electro-mechanical systems (MEMS) technology can exhibit corrosion behavior when subjected to exposure in saline after as few as two days. Much depends on the thickness of parylene packaging. When coatings are thin – less than 5 μm — moisture can diffuse through the parylene under accelerated soak-conditions or exposure to high electric field environments. Contaminants trapped inside parylene coatings lead to structural breakdown. Parylene moisture barrier performance is improved by increasing the thickness of the parylene film.

Corrosion

Although parylene is highly corrosion resistant, problems can emerge when it is used to coat such metallic substances used on medical implants. Addition of a silane layer at levels of 2 μm to the parylene improves corrosion resistance in these cases. However, dramatic destruction of the protective coating can result from the presence of H2O2 in the human body. The deterioration mechanism is sourced by formation of OH-dot radicals on the assembly’s metallic surface and beneath the parylene/silane film, a consequence of the body’s inflammatory response. Degradation processes start at metal/polymer interface and progress towards the outer, parylene surface.

Cracking

While parylene typically offers consistent thermal stability, through ongoing exposure to temperatures of 100°C for as long as 10 years, another parylene failure mechanism, environmental stress cracking (ESC), can occur. ESC can develop when the circuit board’s operating temperature is either too low or too high; the resultant excessive flex in the film stimulates cracked coating. Overly thick applications of parylene to the substrate during the CVD process can cause uneven drying and also lead to surface cracking of the deposited film. Managing deposition pressure toward a lower range will restrain cracking. Reducing coating thickness better controls the coefficient of thermal expansion, as does monitoring appropriate temperature levels.

Delamination

Parylene’s underlying chemical structure can interfere with surface interface, diminishing positive interaction of surface energies between the coating and substrate, limiting adhesion. The resulting delamination separates the conformal coating from the substrate, producing a poor, unacceptable finish characterized by torn, unattached, and non-conformal coating. Coating porosity, demasking, materials-incompatibility, or unclean substrate surfaces may instigate delamination and subsequent lack of parylene adhesion. Using a parylene type that is compatible with the substrate is necessary, as is assuring moisture impermeability and surface cleanliness.

Outgassing

The incidence of parylene outgassing is generally very low, especially in comparison to wet conformal coatings. However, problems from outgassing are a concern for any electronic equipment intended for use in high-vacuum environments, ranging from medical implants to aerospace-based equipment. Substrate and assembly components under the film could outgas, causing issues with the film’s functionality, potentially rendering PCBs inoperative. Outgassing is related to thermal stability; temperatures between 150°C – 220°C and 400°C – 510°C increase the intensity of component outgassing, cross-contaminating surfaces and preventing a direct bond with the reactive monomer, interfering with the parylene film’s effectiveness.

Conclusion

Because of vulnerability to contaminants, cleaning the surface of the substrate prior to coating is crucial to achieving parylene adhesion. Trace contaminants disrupt the bond between parylene film and underlying surfaces. Not always immediately apparent, compromised adhesion will eventually compromise the coating and, ultimately, the end product, thus neutralizing parylene’s protective benefits.

To learn more about how to improve parylene adhesion to limit failures, download our whitepaper:

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !