How Parylene Protects Automotive Electronics

Posted by Sean Horn

Friday, October 21, 2016 7:30

@ 7:30 AM

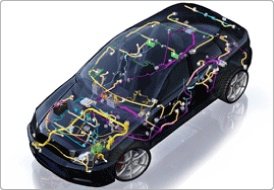

High-tech electronic systems increasingly regulate automotive management functions for emissions’ controls, fuel systems, fluid monitoring, lighting, and powertrain mechanics, frequently comprised of miniaturized, multi-layer MEMS/Nano packages. Systems’ survival in hostile vehicular environments typified by condensation, corrosive fluids and vapors, excessive temperatures, humidity and prolonged UV exposure is partially assured by protective conformal coating.

All types of conformal coating exhibit some degree of physical flexibility, and protection against mechanical/thermal shock, while securing the component from exposure to corrosive elements. Understanding the precise end use of a vehicular printed circuit board (PCB) system is basic to deciding among conformal coatings for automotive application.

Material cost-effectiveness can actually be enhanced with a more expensive initial investment in solutions that continue working without replacement or repair in the longer-term. Wet coatings like acrylic, epoxy, silicone and urethane offer simple application and relatively easy removal, repair and replacement. In contrast, parylene’s specialized chemical vapor deposition (CVD) process is slower-to-finish and considerably costlier to enact. However, because CVD causes parylene to penetrate far deeper into the substrate surface, it generates the highest levels of protection available for many automotive purposes. Parylene is a superior substrate covering for automotive PCBs, providing durable, ultrathin protection for strategically-situated moving parts and related electro-mechanical assemblies.

Expanded Automotive Use of Parylene Conformal Coatings

Electrically insulating, parylene provides long-term surface insulation resistance (SIR) which stimulates optimal function of such automotive system as:

- analytical performance measurement of automotive systems’ functioning,

- anti-lock brakes control,

- emissions’ management,

- engine control unit (ECU),

- instrument pods’ circuitry (IPC),

- power controls/modules for doors, mirrors, seats, sunroof, and windows,

- power train/chassis operations,

- passenger comfort/convenience, and

- tire-pressure gaskets/seals.

With parylene, PCBs and related operational equipment benefit from enhanced functional integrity, despite ongoing exposure to operational ecosystems characterized by the presence of acidic substances, chemical contaminants, fluctuations of electrical current, humidity, moisture, temperature changes or a mixture of these conditions.

With parylene, PCBs and related operational equipment benefit from enhanced functional integrity, despite ongoing exposure to operational ecosystems characterized by the presence of acidic substances, chemical contaminants, fluctuations of electrical current, humidity, moisture, temperature changes or a mixture of these conditions.

Providing chemical, dielectric, moisture and thermal protection that far surpass competitive coatings for automotive purposes, parylene is the conformal coating of choice for such applications as:

- PCBs in contemporary automobiles that contain approximately 100 million lines of code and have advanced circuitry with scores of microprocessors. Parylene coatings’ excellent dielectric properties provides insulation that permits PCB traces to be situated closer together, reducing the potential for nearby electronics interference with performance, while diminishing component size.

- Microelectricalmechanical Systems (MEMS) that manage signal-processing and communication functions. Such electronic vehicular systems as manifold air pressure (MAP), manifold air temperature (MAT), and power train/chassis control are regulated by MEMS’ sensors. Frequently situated in areas of high performance activity and stress, MEMS’ sensor maintenance is essential to assure safe, efficient automotive performance. Of conformal coatings, parylene best safeguards micro-machined circuits from the potentially deleterious effects of aggressive automotive environments.

- Ruggedization of automotive components and systems stabilizes performance through exposure to harsh engine fluids, high levels of vibration, and temperature extremes. Parylene is well-adapted to ruggedization, providing superior resistance to heavy vibrations and shock/internal disruption within the engine, for such automotive systems as detection/door switches, environmental protection monitors, mechanical/physical performance gauges, motion controllers, and components regulating safety, rocker and tactile functions. Parylene is applicable for specialized, highly refined purposes, where sensors and components need to be appropriately insulated.

- LED illumination is increasingly essential to safe driving. Parylene conformal coatings extend the functional life of the LED light itself, improving performance.

- Elastomer/polymer seals normally confronted by harsh operating conditions benefit from parylene films, which stimulate enhanced operational efficiencies and consequent functional upgrades. This can be especially true in the case of older, high-mileage vehicles, where systems have already experienced considerable use. Such automotive communicative functions as GPS, vehicle telemetry, and voice/data systems (WiFi/Bluetooth) also benefit from application of parylene film

Conclusion

Increasing computerization of automotive systems is applied to virtually all a vehicle’s operational technology. Often situated in demanding end-use environments, PCBs, electronic sensors and similar assemblies benefit from application of parylene conformal coatings.

Parylene CVD processes generate both:

- deep penetration of the component substrate and

- the thinnest possible effective layers of pinhole-free conformal coating for automotive assemblies,

- supporting their function in even the most spatially-confined segments of any automotive engine,

- in the presence of various combinations of aggressive chemicals, harsh liquids and vapors.

Parylene conformal coatings significantly lessen the likelihood of performance degradation in automotive environments characterized by persistent exposure to corrosive engine liquids and byproducts, winter road-salts, mechanical vibration, noxious exhaust gases, and fluctuating thermal conditions.

Parylene coatings also provide dependable component protection for automotive computers.

Rapidly evolving products for automotive information technology (IT), electrical systems, engine components and sensors increasingly depend on parylene coatings to assure ongoing performance through all conditions. Parylene protects assemblies and systems within the engine, while adding to the functional performance, better assuring the vehicle operates as intended.

If you’re looking for parylene coating services for automotive electronics, contact Diamond-MT today. Get started by calling us at 814-535-3505 or completing a quote request.

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !