How Parylene Protects Electronics in Harsh and Hostile Environments

Posted by diamondmtblog on Wed, Jul 28, 2021

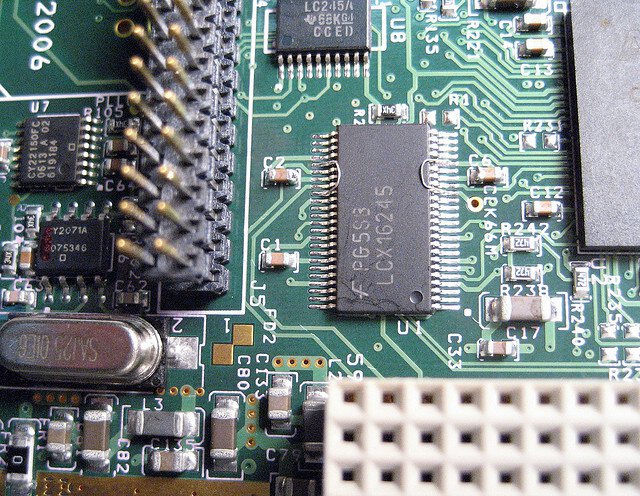

Parylene comes from a series of polymers from paraxylene and is often used as a coating that safeguards electronic devices. Specifically, parylene coating is a conformal coating created directly on surfaces at room temperature using a chemical vapor deposition (CVD) process. For many facilities and industries, parylene shields electronics from contamination, corrosion and complications arising

0 Comment Click here to read/write comments