Different Types of Masking for Conformal Coatings

Posted by Sean Horn on Fri, Jan 13, 2017

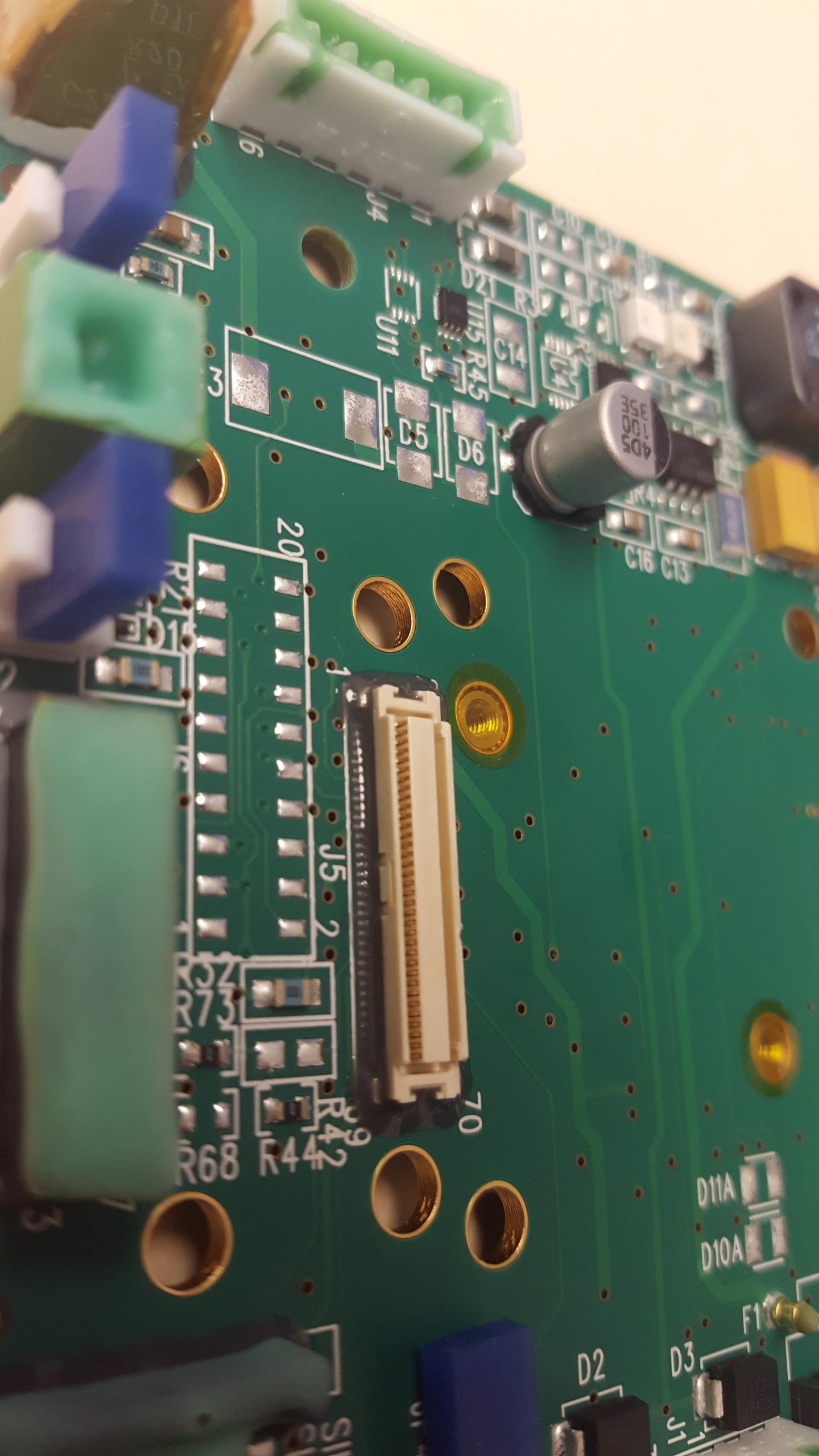

Masking For Conformal Coating Printed circuit boards (PCBs) and related electrical assemblies benefit from the protection of conformal coatings. However, because the films are insulative when dry, they can disrupt operation of the assemblies’ electrical components, items like capacitors, connector contacts, diodes, operational amplifiers, resistors, or transistors. Conformal coating masking

0 Comment Click here to read/write comments