What Solvent Breaks Down Parylene?

Posted by Sean Horn

Friday, March 3, 2017 7:21

@ 7:21 AM

While parylene provides a reliable, versatile conformal coating, it can require removal. When circumstances necessitate removal of liquid coatings – acrylic, epoxy, silicone or urethane – a wide range of chemical solvents can be used to detach the film from the underlying substrate. No single chemical material/process is equally successful for all uses, but solvent processes are employed most frequently because they do the least damage to printed circuit boards (PCBs) and their components. Such is not the case with parylene.

Although application of parylene is based on a specialized chemical vapor deposition (CVD) process, the substance itself is chemically inert, and is seldom amenable to solvent removal processes. Because of parylene’s exceptional chemical resistance, solvent stripping techniques routinely utilized for liquid conformal coatings are ineffective. Other methods — abrasive, mechanical, plasmatic and thermal – are more dependable for removing parylene, generating far reduced impairment to PCB components.

Parylene Resistance to Solvents

Investigation of the impact of organic solvents on parylenes N, C and D has shown they are insoluble up to 150ºC, resisting solvents’ removal capacities. Organic solvents like chlorinated aromatics (chlorobenzene and o-dichlorobenzine) or fluorinated trichlorotrifluoroethane produce limited, and entirely reversible, swelling effects on parylene, with increased film thickness maxing-out at 3%. Stress-cracking agents such as Igepal or Hostepal similarly lack the power to separate parylene films from substrate surfaces.

Diluted inorganic reagents like deionized water, 10% solutions of sodium or ammonium hydroxide, and hydrochloric or sulfuric acid also have little effect on parylene coatings. Severe film degradation can be generated by nitric acid under harsher conditions, where PCBs are left exposed at 75ºC for 30 minutes. Coating subjected to hydrochloric acid under the same conditions swelled at rates as high as 8.2% and suffered some discoloration.

None of these solvents sufficiently break down parylene conformal films to stimulate its removal from the substrate.

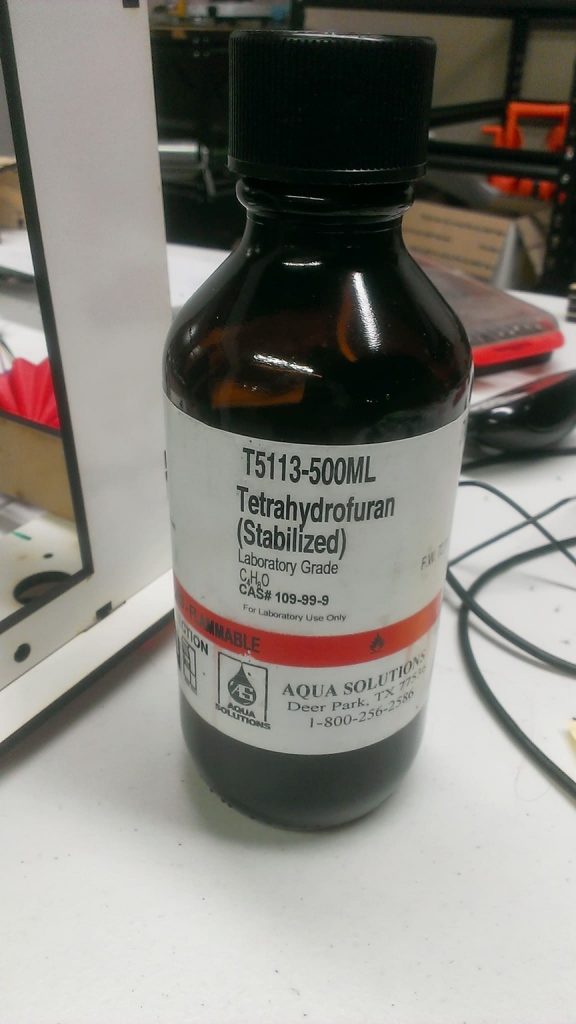

Tetrahydrofuran (THF) Chemical Removal for Parylene

A colorless organic compound, THF is water-miscible: miscibility is:

- the property of substances to fully dissolve in each other at any concentration,

- mixing completely in all proportions, while

- forming a homogeneous solution.

Also known as oxolane, THF demonstrates strong coordination and low viscosity at standard pressure/temperature, used either independently or in mixture, permitting dependable control of the removal process. It’s chemical formula is (CH2)40.

Displaying a high dielectric constant (DC) of 7.6, THF is a polar aprotic solvent, lacking an acidic hydrogen; it will dissolve salts, as well as a wide range of nonpolar and polar chemical compounds. THF also readily donates protons (H+) to reagents, accepting hydrogen bonds. Other properties include a:

- boiling point of 66°C,

- density of 0.886 g/mL, and

- dipole moment (D) of 1.75 D.

THF successfully removes parylene coatings from substrates. For example,

- parylene C coating with a thickness of .001 mm. is removed following immersion between 2 – 4 hours in a THF solvent.

- Parylene separation is initiated during immersion.

- The assembly is then lifted from the THF solution, rinsed in alcohol and allowed to dry.

- Tweezers are used to gradually detach the parylene film from the assembly’s surface.

This procedure is standard, although solution strength and immersion time vary according to parylene type (C, D, N, etc.) and coating thickness.

Only THF provides a reliable chemical basis for removing parylene coatings from assembly substrates below the melting point; other options are highly specialized and seldom applied. Both chloronaphthelene (C10H7Cl) and benzolyl benzoate (BnBzO) have demonstrated success removing parylene from substrates at temperatures of 175°C or greater. For instance, conformal films made of parylene C can be dissolved by either C10H7Cl or BnBzO above 175ºC; for parylene N the level is 265ºC. Nevertheless, these chemicals remain incompatible with most current practical parylene processes, and are infrequently applied for conformal coating removal.

Conclusion

Parylene’s chemical inertness restricts chemical removal of conformal films in virtually all cases. Colorless and miscible in water, with a boiling point of 66ºC (DC = 7.6, 1.75 D), Tetrahydrofuran (THF, oxolane) is a versatile solvent that successfully removes parylene coatings from PCB assemblies. With the exception of oxidizing agents, parylene is also inert to inorganic reagents, a condition further pointing THF’s value for film removal purposes.

Diamond-MT provides high-quality parylene conformal coating and removal services. To learn more about our offerings and discuss your next project’s needs, contact our team of experts by calling 1-814-535-3505 today.

To learn more about solvents and parylene, download our whitepaper:

{{cta(‘67972768-ab7a-4367-83ee-db9ddf93913c’)}}

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !