How Long Does Parylene Coating Last?

Posted by Sean Horn on Fri, May 22, 2020

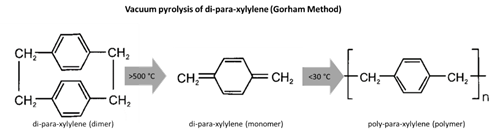

The stability and insulation property of parylene conformal coating is critical for the reliable operation of electronic devices throughout their lifetime (PCBs, MEMS, sensors, implants and so on.). The failure mechanism of the conformal coating layers is known to be due to pore formation, blistering, delamination and thinning or pinhole formation due to dielectric breakage […]

0 Comment Click here to read/write comments