How Fast Does Parylene Deposit?

Posted by Sean Horn on Fri, Nov 20, 2020

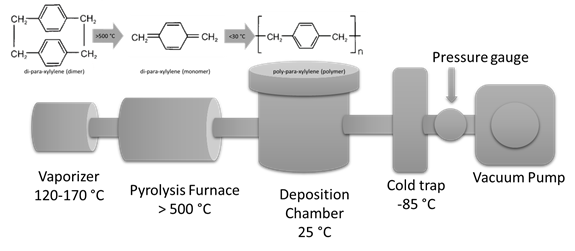

Parylene conformal coatings combine a number of properties that are attractive for use in a wide spectrum of applications. Their low dielectric properties, high mechanical strength, transparency, bio compatibility, chemical inertness against all of the common acids, bases and organic solvents, low water/gas permeability and thermal properties make them interesting for use in many industries. [&hel

0 Comment Click here to read/write comments