Parylene Effectiveness at Different Thicknesses

Posted by Sean Horn on Fri, May 4, 2018

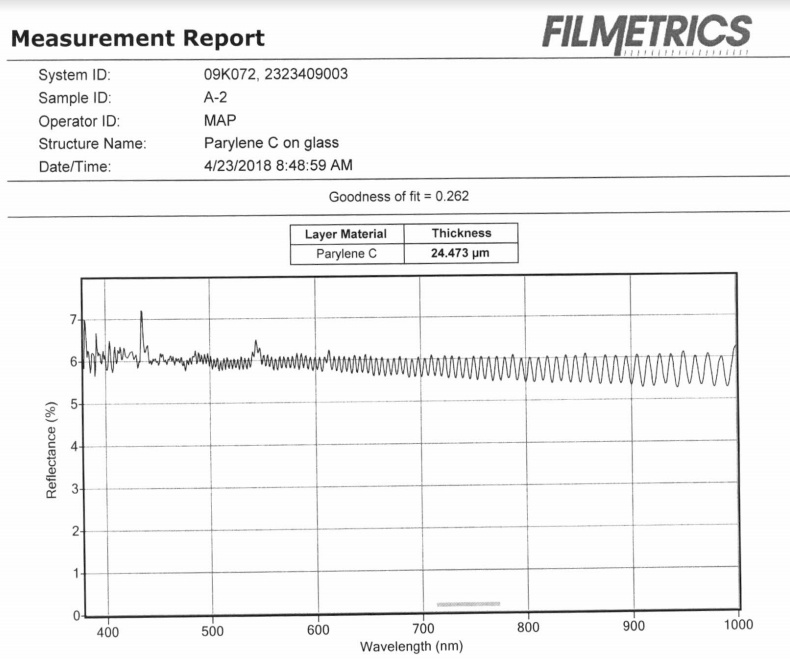

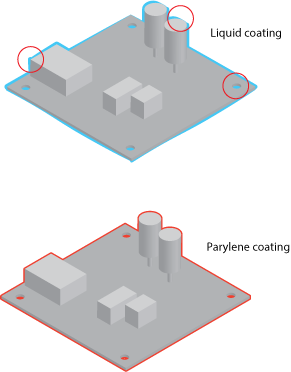

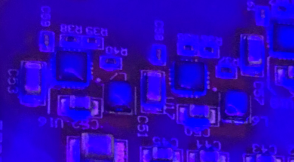

Each conformal coating material exhibits a range of unique performance properties that determine its product uses. Relevant factors include the required coating-thickness necessary to assure reliable performance. Like other coating types, parylene (XY) layer thickness is largely a function of several factors: (1) substrate material, (2) the kind of assembly being covered, and (3) its [&helli

0 Comment Click here to read/write comments