All about the Conformal Coating Process

Posted by Sean Horn

Friday, June 2, 2017 7:40

@ 7:40 AM

Liquid application resins acrylic, epoxy, silicone and urethane are applied to electronic circuitry in a liquid format by brush, dip or spray techniques, either manually or through robotic processes; they require curing before they can be used.

Parylene’s specialized chemical vapor deposition (CVD) process transforms powered parylene dimer to a gas, which permeates substrate surfaces; the result is a uniform, pinhole-free protective covering; parylene requires no curing.

Regardless of the type, all conformal coatings safeguard PCBs, medical devices, and other items from developments that could stimulate component dysfunction or shut-down, if left unchecked. Among the most common of these conditions are:

- chemical incursion,

- contamination (particulate or otherwise),

- humidity/moisture, and

- temperature extremes.

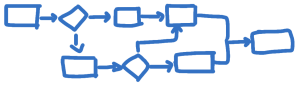

Basic Conformal Coating Processes

Acquiring order specifications is the initial step in the conformal coating process. This should include all pertinent information, including such factors as identifying:

- required coating thickness,

- those keep-out areas of the component NOT to be conformally coated,

- materials most appropriate to coating requirements, and

- acceptance criteria.

Process development depends upon whether wet or CVD materials are used. Liquid coating processes need explicit instructions concerning whether brush, dip or spray methods will be used, with further focus on tooling – brush/nozzle-types, pallets, etc., machine program requirements, and selection of the correct cure procedure. Non-cured parylene CVD processes also need to be enacted according to client specifications.

Process development depends upon whether wet or CVD materials are used. Liquid coating processes need explicit instructions concerning whether brush, dip or spray methods will be used, with further focus on tooling – brush/nozzle-types, pallets, etc., machine program requirements, and selection of the correct cure procedure. Non-cured parylene CVD processes also need to be enacted according to client specifications.

Inspecting the components to be coated is essential to detect the presence of a wide range of contaminants – chemicals, dust, moisture — that can interrupt the unfettered flow of electrons through the circuit, leading to degraded performance accuracy. Cleanliness testing helps detect contaminants; where required, cleaning is performed at this time.

Insulative conformal films can interfere with the function of electrical components; thus, items like connectors and test points, and similar keep-out areas, require masking. Prominent variables of the masking process include the coating-type, the PCB’s surface geometry, the component to-be-masked, and overall production volume. Once completed, masking inspection verifies compliance with the client’s masking drawing. Masking processes enacted prior to coating application assure the conformal materials DO NOT invade designated keep-out areas.

The most common liquid application methods are:

- Brushing: Implemented on a piece-by-piece basis. Used less frequently because quality-of-outcome relies on the very variable manual skill of the operator; uniform coating thickness and bubbling are difficult to control. Slow process, employed mostly for low-volume coating assignments and repair.

- Dipping – Immersing PCBs in a coating solution is fast, the most commonly-used method for most high-volume applications; requires conscientious preparation to ensure the coating does not penetrate improperly masked keep-out areas. Variables include rates of immersion/withdrawal, and viscosity of the coating material.

- Spraying – A good choice for medium- and higher-volume applications, spraying generates reliable conformal films; substrate cleanliness is essential, as is superior film-adhesion. The objective is obtaining a combination of solvent dilution, nozzle pressure, and spray-pattern to meet assignment objectives; spray coating is readily automated.

Robotic technology can selectively coat circuit boards using the processes described above, generally faster and more accurately than manual application. Robotics generate advantages like varied flow rates/vacuum pressure for dipping, and better-controlled viscosity while spraying.

Liquid coatings require curing and drying following application, to ensure correct film consistency/thickness. Drying must be implemented in the appropriate environment, depending upon the specific parameters of the coating assignment and type of coating used; in some cases, curing can last longer than 30 days at room temperature.

Raw, powdered parylene dimer is heated and the solid-state parylene is transformed into vapor at the molecular level, sublimating each gaseous molecule, dividing each into a monomer. Parylene vapor attaches to the substrate one molecule-at-a-time. The monomer gas reaches final deposition phase in the cold trap, where temperatures are cooled to levels between -90º and -120º C, removing any residual parylene materials from the substrate. The coated assembly requires NO curing or solvent catalysts.

De-Masking

De-masking occurs after the coating has been applied, but before the curing for liquid coatings. This results after curing for liquid coatings; parylene requires no curing. In either case, the masking material is removed, as soon as possible after the dried coating is firm enough to handle, but sufficiently soft to prevent tearing the film during removal. Contacts and other masked regions of the PCB are exposed, ready to perform their electrical functions.

If masking is poorly implemented, conformal coating can seep under the tape because of bleeding/leaking during film application, necessitating de-masking.

Touch-up

Failure to stop coating penetration into keep-out areas can require costly, time-consuming repairs as fixing the leak, removing the conformal coating from the assembly, replacing the improperly masked component, or scrapping the entire assembly. Conditions like delamination or tin-whiskers can also compel touch-up. The process is job-specific, dependent on the type of coating material, its position on the PCB, and the board’s components.

Chemical solvents do the least damage to PCBs, and are effective for liquid coatings. Most chemical methods don’t work less well for chemically-inert parylene films; only tetrahydrofuran (THF) consistently removes parylene from substrates. Abrasion, laser, mechanical, plasmatic and thermal removal methods are more successful for parylene films; they also work for liquid coatings in many cases.

Touch-up generally entails spot removal from specific regions of the PCB. In most cases, the selected coating can be reapplied, effecting repair. When completed, a thorough, pre-shipment inspection is enacted for quality assurance.

To learn more about the conformal coating process, download our whitepaper now:

{{cta(’63a4423d-e341-4ba6-b331-0758fbf8022e’)}}

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !