Parylene for Medical Sensors

Posted by Sean Horn

Friday, September 28, 2018 7:30

@ 7:30 AM

Many medical devices rely on sensors to detect and measures conditions affecting patient health. Generally, physical properties within the body – heartbeat, blood pressure, breath rate, temperature, — are recorded and transmitted to medical personnel/technology, allowing continuous physiological monitoring of health-specific disorders, to improve the quality of diagnosis and treatment.

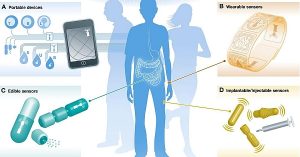

Often, sensors are components of devices implanted directly into the body. Miniaturization, customization, and integration of multiple sensors in a single device permit easier positioning within the body, while simultaneously generating more and better data to enhance diagnosis/treatment options. External, wearable sensored devices can be surprisingly inobtrusive, providing dependable information from articles like wristbands/watches, headphones and smartphones, or hats and shoes. A third category of medical-grade sensors are stand-alone devices.

Protecting Sensor Function

Implantables must function without fail within the body and, as such, require exceptional protection to maintain performance through often harsh inner-body environments. The polymer parylene (XY) is well-situated to generate the necessary operational security. Biocompatible, its pinhole-free, truly conformal coatings provide sensor protection, resisting water and body sweat, as well as bodily fluids, chemicals, corrosives, and solvents. In addition, XY’s ultra-thin film layers (IPC standard/10-50 microns) support implantable positioning within often minute bodily spaces.

Rapid progress in both sensor and conformal coating technology has contributed to the evolution of parylene protected medical sensors. Until recently, sensors’ physical size made it too difficult for implantable or wearable tech-use. Newer miniaturized circuits and enhanced microcontroller functions have stimulated development of microelectricalmechanical (MEMS) and nano (NT) systems, small enough to be readily positioned throughout the body’s interior. XY micro-thin films offer coating protection without jeopardizing sensor location at critically confined sites within the body, permitting acquisition of on-time physiological and movement data that expands the capabilities of digital health monitoring systems and patient care.

In addition to biocompatibility and biostability, parylene is extremely lightweight and almost impossible to penetrate. XY conformal films can be precisely deposited on virtually all available sensor materials with secure adhesion. Much has to do with parylene’s unique chemical vapor deposition (CVD) process. Generating a durable, pinhole-free conformal film on complex implant shapes, CVD is successful covering a wide range of substrate/product materials, including ceramic, composite, and metallic substances.

Chemical-vacuum polymerization converts powdered parylene dimer into a vapor. XY literally “grows” on device surfaces at a molecular level. The resultant conformal film covers all sensor surfaces, including the smallest crevices. Only microns thick, the biocompatible barrier tightens all areas on multi-layer sensor elements with a uniform coating of manageable thickness, supporting the device’s performance requirements.

- In-process synthesis — coating composition uses no catalysts, fillers, plasticizers, solvents or stabilizers.

- No additional curing, cross-linking or related processes after CVD is complete.

- Excellent pinhole-free, secure barrier protection.

- Micro-thin film layers controlled to precise thickness specifications.

- Exceptional hydrophobic properties without toxic outgassing.

- Dependable elastometricity.

- Functional stability in the presence of bodily fluids, while remaining

- chemically inert and non-reactant with the carrier polymers or drugs.

In addition to IPC standards, XY thicknesses can vary between 500 angstroms and 75 microns. At 25 microns, parylene coating displays an electrical insulating capability of up to 7,000 volts, far exceeding the protection levels of liquid coating materials at that thickness.

` In all cases, biomedical sensors and related hybrid flexible sensing platforms record real-time physiological activities of organs and tissue. Situated at sites ranging from the brain to the bladder, parylene coated sensors’ biocompatibility assures no damage to surrounding tissues. In addition to biostability, XY sensors produce longer-term functionality through corrosion resistance, film durability, enhanced lubricity, and sufficient surface consolidation of dusting or flaking. Among sensor types relying on XY conformal protection are:

- Surface acoustic waves (SAWs) technology, which detect antibody film levels/cell volume used for oxygen plasma treatments.

- Electrochemical impedance spectroscopy (EIS) devices, which relay data pertinent to cervical smears/urinary bladder infections.

- Electromyographic (EMG) microelectrode arrays/endoscopic equipment.

Highly biocompatible, biostable and non-toxic, parylene conformal films integrate well in the human body, adapting to soft tissues, promoting longer-term bodily acceptance. Micron-thin XY coatings provide sensors this exceptional resilience and protection without adding significant dimension or weight. MEMS/NT diagnostic monitoring sensors are especially well-served by XY’s insulating, pinhole-free conformal protection, minimizing potential leakage into the bodily system during use. Only CVD-applied parylene generates these specialized service features for internal medicine.

To discover more about parylene and sensors, download our whitepaper now:

Download our guide on Parylene 101

Comments

Homepage 4/17/2020. 10:17:10 AM

... [Trackback] [...] Informations on that Topic: blog.paryleneconformalcoating.com/whats-the-difference-between-potting-and-conformal-coating/ [...]

londondrugscanada.bigcartel.comlondon-drugs 4/17/2020. 10:17:10 AM

cialis uk https://londondrugscanada.bigcartel.com/london-drugs This is nicely expressed. !