Can Color be Added to Parylene?

Posted by Sean Horn on Fri, Oct 9, 2020

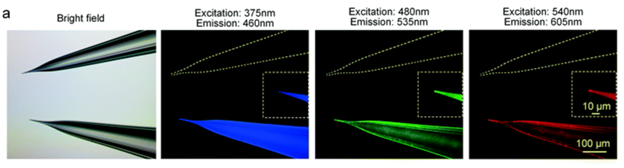

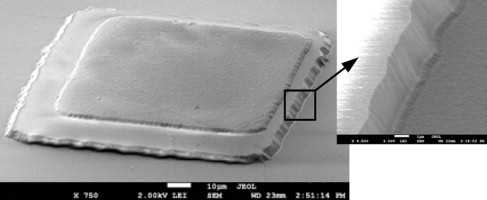

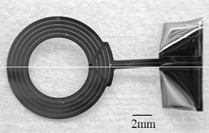

Parylene is a conformal coating exhibiting extraordinary properties such as high mechanical strength and biocompatibility. It is a transparent (colorless) film in the UV-V is range of the solar spectrum (Parylene N and C absorb below ≈280 nm). The high transmittance of the polymers in the visible region (90%) make them eligible for use in […]

0 Comment Click here to read/write comments